Product info

Item Code

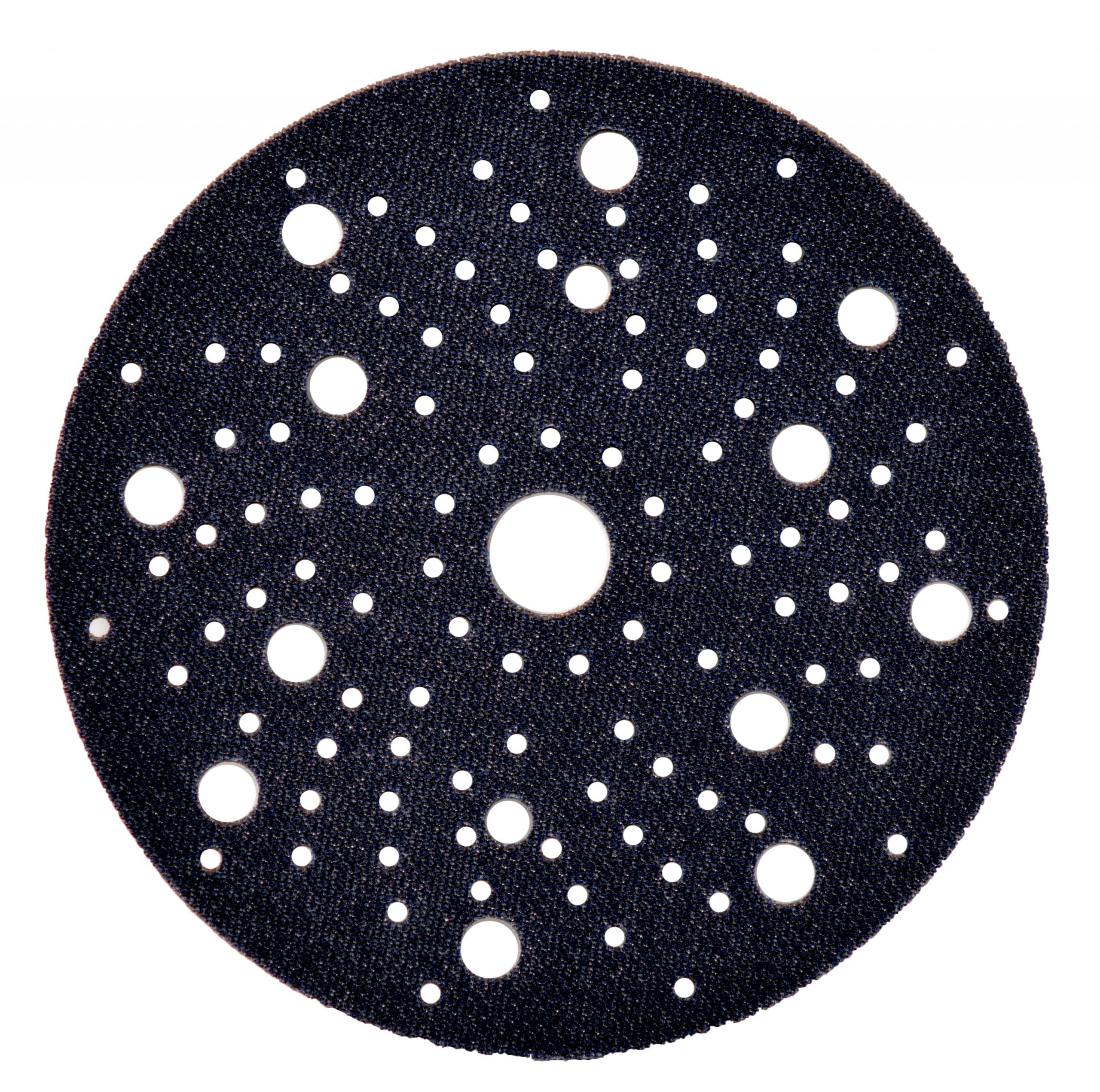

3M™ Hookit™ Soft Interface Pad, 150 mm x 10 mm, Multihole, Soft, 51127

Tags:

Technical info

Technical Information

3m™ hookit™ soft interface pad, 150 mm x 10 mm, multihole, soft, 51127

- soft foam construction conforms to contours for a finer finish

- adds support to disc pad for improved abrasive cut and closer edge sanding

- applies effortlessly between hookit™ discs and hookit™ back-up pads for quick changeouts

- hole configurations help clear dust from the work surface, increasing disc life

maximise cushion and conformability during the automotive sanding process with 3m™ hookit™ soft interface pad. use our pads between hookit™ discs and hookit™ back‐up pads for quick change outs.

for smoother and more refined finishes, use 3m™ hookit™ soft interface pad. used between our hookit™ back‐up pads and hookit™ abrasive discs, they add cushion and conformability for automotive sanding applications requiring precision across uneven surfaces. it also reduces the vibration common when using a dual action orbital sander, increasing the clarity of the finish.

Feature info

Feature Information

3m™ hookit™ soft interface pad, 150 mm x 10 mm, multihole, soft, 51127

- soft foam construction conforms to contours for a finer finish

- adds support to disc pad for improved abrasive cut and closer edge sanding

- applies effortlessly between hookit™ discs and hookit™ back-up pads for quick changeouts

- hole configurations help clear dust from the work surface, increasing disc life

maximise cushion and conformability during the automotive sanding process with 3m™ hookit™ soft interface pad. use our pads between hookit™ discs and hookit™ back‐up pads for quick change outs.

for smoother and more refined finishes, use 3m™ hookit™ soft interface pad. used between our hookit™ back‐up pads and hookit™ abrasive discs, they add cushion and conformability for automotive sanding applications requiring precision across uneven surfaces. it also reduces the vibration common when using a dual action orbital sander, increasing the clarity of the finish.